In the fast-paced world of logistics and material handling, the importance of reliable and efficient transportation systems cannot be overstated. At the heart of this functionality lies an often-overlooked component: conveyor belts. Rubber conveyor belts, along with their PVC counterparts and rubber drive belts, form the backbone of countless industries, seamlessly moving products from one point to another. As the unsung heroes of logistics, these belts are essential for achieving optimized workflow and enhancing productivity in various settings.

The design, development, and production of rubber conveyor belts, PVC conveyor belts, and rubber drive belts have evolved significantly over the years. Innovations in materials and technology have made these belts not only more durable but also versatile enough to handle diverse applications. From manufacturing plants to distribution centers, these conveyor systems play a crucial role in ensuring that operations run smoothly and efficiently, often without receiving the recognition they deserve. Recognizing their vital contributions helps us appreciate the intricate workings of modern logistics.

The Evolution of Conveyor Belt Technology

The journey of conveyor belt technology began in the late 18th century when simple leather and fabric belts were used to move materials. Early designs focused on practicality, enabling goods to be transported more efficiently than manual labor. As industrialization took hold, the demand for more durable and reliable systems increased, leading to innovations in materials and construction techniques.

With the advent of rubber in the late 19th century, conveyor belts experienced a significant transformation. Rubber conveyor belts offered superior strength and flexibility compared to their predecessors, allowing for the handling of heavier loads and more diverse materials. This development led to the growth of industries like mining and manufacturing, where the need for efficient logistics became paramount.

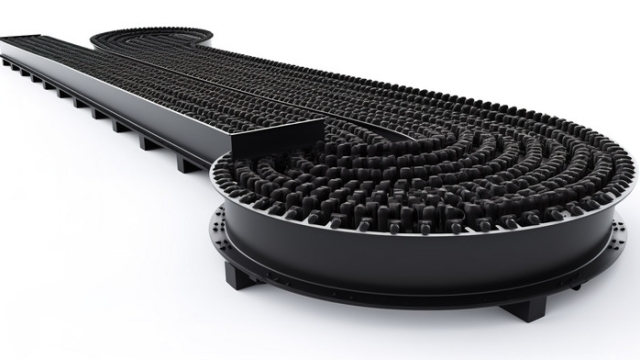

In the modern era, advancements in technology have further revolutionized conveyor belt systems. The introduction of PVC conveyor belts and specialized rubber drive belts has expanded the applications of conveyor systems. These innovations are tailored to meet the demands of various industries, from food processing to automotive, ensuring optimized performance and reliability in the design, development, and production of conveyor belts.

Key Materials and Their Impact on Performance

The performance of conveyor belts largely depends on the materials used in their construction. Rubber is a primary material due to its excellent elasticity, strength, and durability. Natural rubber provides superior flexibility and shock absorption, making it ideal for applications involving heavy loads and dynamic movements. The addition of synthetic compounds can enhance properties such as oil resistance and temperature tolerance, ensuring the belts withstand harsh operating conditions.

PVC, or polyvinyl chloride, is another important material in the realm of conveyor belts. Its lightweight nature and resistance to abrasion and chemicals make it a popular choice for many applications, particularly in food processing and packaging sectors. PVC conveyor belts can be designed with smooth or textured surfaces to optimize material handling, and their affordability often makes them a go-to option for businesses looking to balance cost with performance.

Rubber drive belts, while serving a different function compared to conveyor belts, also rely heavily on high-quality materials for efficiency. These belts are often made from a blend of synthetic rubbers and reinforcing fibers, which provide the necessary grip and tensile strength to transmit power effectively. The choice of materials in rubber drive belts can significantly impact their longevity and performance, highlighting the importance of careful material selection during the development and production stages.

Applications and Advantages in Logistics

Rubber conveyor belts are vital in various logistics applications, showcasing their versatility and efficiency. They are commonly used in warehouses, distribution centers, and manufacturing plants to streamline the movement of goods. Their ability to handle heavy loads and resist abrasion makes them an ideal choice for transporting materials such as aggregates, coal, and packaged products. This adaptability ensures that operations can maintain high productivity levels while minimizing downtime.

PVC conveyor belts are another essential component of modern logistics systems. These belts are known for their lightweight construction and resistance to various environmental factors, making them suitable for handling food products, pharmaceuticals, and other sensitive materials. The availability of different surface textures and colors allows for customization to meet specific industry requirements, enhancing both functionality and safety during transportation. This flexibility significantly contributes to efficiency in diverse logistic processes.

Rubber drive belts also play a crucial role in powering conveyor systems within logistics frameworks. These belts provide reliable performance and durability under challenging conditions, ensuring that machines operate smoothly and efficiently. Their design allows for a snug fit and excellent grip, which translates to improved energy transfer and reduced wear over time. As a result, these drive belts help maintain operational consistency, ultimately leading to cost savings and better resource management in logistics operations.