As the brush manufacturing sector continues to innovate in response to the demand for efficiency, many companies are now advertising Brush Production Equipment for Sale to keep up with the advancements in automated assembly processes.

As the brush manufacturing sector continues to innovate in response to the demand for efficiency, many companies are now advertising Brush Production Equipment for Sale to keep up with the advancements in automated assembly processes.

In today’s fast-paced manufacturing landscape, the demand for efficiency and precision has driven significant innovations in automated assembly processes. One industry that is witnessing remarkable advancements is the brush manufacturing sector, where automation plays a crucial role in enhancing production capabilities. Companies are increasingly turning to automated brush machine assembly lines to improve consistency, reduce labor costs, and meet the ever-growing market needs.

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands out as a leader in this field. With 37 years of production experience, the company specializes in the development of 2-5 axis machines that are tailored to the intricate requirements of brush production. Their expertise and technical accumulation have paved the way for groundbreaking advancements in automation, ensuring that manufacturers can achieve high-quality outputs with greater efficiency.

Company Overview

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands as a leading player in the brush machine industry, with a remarkable 37 years of experience. Established with a vision to innovate, the company has dedicated itself to manufacturing high-quality machines tailored for the comb and brush production sector. Their commitment to excellence and adherence to industry standards have positioned them as a trusted partner for many businesses worldwide.

The company specializes in the production of advanced 2-5 axis machines, which are designed to enhance the efficiency and precision of the assembly lines. With a focus on automation, Jiangmen Meixin understands the demands of modern manufacturing, providing solutions that meet the evolving needs of their clients. Their technical expertise and continuous investment in research and development ensure that they remain at the forefront of technological advancements.

Jiangmen Meixin places a strong emphasis on customer satisfaction, striving to build long-term relationships with their partners. By offering a range of customized solutions and exceptional after-sales support, the company aims to empower manufacturers to maximize their productivity and quality. This dedication to service, combined with their extensive knowledge and experience, makes Jiangmen Meixin a reputable name in the comb and brush making machinery market.

Machine Technologies

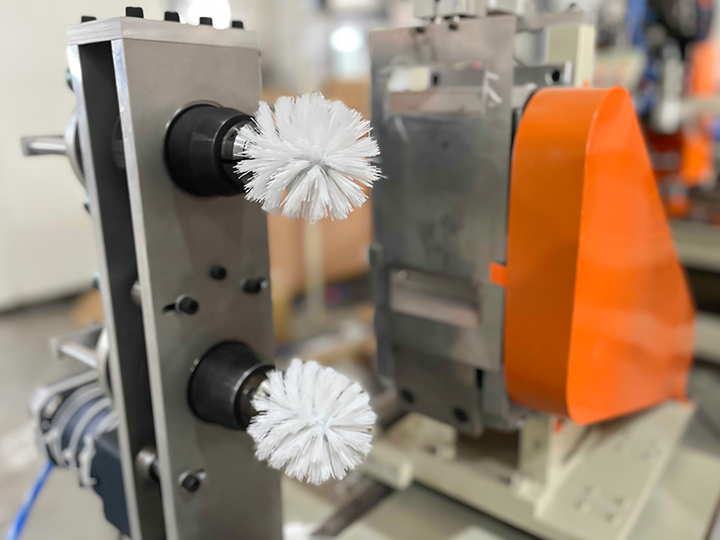

The advancements in machine technologies for brush manufacturing have revolutionized the production process, enhancing both efficiency and precision. Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. specializes in 2-5 axis machines that are designed to automate various stages of brush assembly. These machines utilize sophisticated software and hardware integrations that allow for real-time monitoring and adjustment, ensuring that each brush meets stringent quality standards.

Moreover, the integration of robotics into the assembly line has significantly reduced manual labor and increased production speed. Automated brush machines can perform complex tasks, such as drilling, trimming, and tufting, with a high degree of accuracy. The 37 years of experience that Jiangmen Meixin brings to the table enables them to refine these technologies continuously, offering machines that are not only reliable but also adaptable to the evolving needs of the market.

Furthermore, the continuous technical accumulation at Jiangmen Meixin has led to the development of energy-efficient machines that minimize waste and reduce operational costs. Innovative features such as predictive maintenance and smart diagnostics empower manufacturers to maintain peak performance without significant downtime. This commitment to technological innovation positions Jiangmen Meixin as a leader in the brush machine industry, driving future advancements in automation and efficiency.

Production Efficiency

The production efficiency of automated brush machine assembly lines has seen significant advancements, particularly with the integration of 2-5 axis machines. These machines allow for precise and coordinated operations, resulting in faster production cycles. With Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. leading the way, manufacturers can achieve higher output levels without compromising on quality. This increase in efficiency not only boosts productivity but also minimizes operational costs.

Moreover, the automation of repetitive tasks has greatly reduced the margin for human error. By utilizing advanced robotics and computer numerical control technology, brush manufacturing can be streamlined, ensuring consistent product quality across large volumes. Jiangmen Meixin’s 37 years of experience in this field have enabled them to refine these automated processes, making assembly lines more reliable and efficient in delivering finished products.

In addition to enhancing speed and accuracy, modern assembly lines also allow for flexible production runs. The adaptability of these automated systems makes it easier for manufacturers to switch between various brush designs and specifications without significant downtime. This flexibility is crucial in meeting the dynamic demands of the market, positioning companies like Jiangmen Meixin as leaders in innovation within the brush manufacturing industry.

Market Applications

The innovations in automated brush machine assembly lines have significantly impacted various industries, including automotive, household cleaning, and personal care. In the automotive sector, automated brush machines are essential for producing high-quality brushes used in vehicle maintenance and parts cleaning. The precision and efficiency offered by these machines help manufacturers streamline their production processes, ultimately enhancing the durability and effectiveness of the products.

Household cleaning applications have also greatly benefited from advancements in brush machine technology. With the rise of smart home devices, there is an increasing demand for brushes that can clean and maintain various surfaces effectively. Automated brush machinery from companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. is designed to meet these needs, enabling manufacturers to produce a wide array of innovative cleaning tools that cater to modern consumer preferences.

In the personal care industry, automated brush machines are crucial for the mass production of specialized brushes for cosmetics and grooming. The ability to customize brushes based on size, shape, and material ensures that personal care brands can offer products that enhance user experience. With 37 years of expertise, Jiangmen Meixin is at the forefront of providing solutions that enable companies to stay competitive in the ever-evolving market.

Future Innovations

With the rapid advancement of technology, the future of automated brush machine assembly lines looks remarkably promising. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. are at the forefront, continuously enhancing their 2-5 axis machines by integrating artificial intelligence and machine learning. These innovations will enable machines to self-optimize based on real-time data and performance metrics, significantly boosting efficiency while reducing waste.

Moreover, the integration of robotics into assembly lines will revolutionize the production process. Automated robotic arms, guided by sophisticated algorithms, will allow for precise placement and manipulation of materials, ensuring higher accuracy and consistency in output. This not only elevates product quality but also enhances safety by minimizing human involvement in hazardous tasks.

Finally, sustainability will play a crucial role in the future of brush machine manufacturing. Companies are focusing on developing environmentally friendly materials and energy-efficient machines. Innovations in recycling processes for materials used in brush production will be a game changer, allowing for a circular economy approach, where waste is minimized, and resources are reused effectively. This shift towards sustainable practices will not only meet regulatory demands but also attract eco-conscious consumers in the growing market.