Are you tired of spending valuable time and effort manually wrapping your pallets? Look no further! In this ultimate guide, we will delve into the world of pallet wrappers and stretch wrap machines, providing you with valuable insights and tips to maximize efficiency in your packaging process.

Gone are the days of struggling with bulky rolls of stretch wrap and inconsistent wrapping results. With the advent of pallet wrappers and stretch wrap machines, businesses can now streamline their packaging operations, saving both time and money. By automating the pallet wrapping process, these innovative machines ensure a precise and uniform application of stretch wrap, leading to enhanced load stability and reduced material waste.

Whether you’re in the manufacturing, distribution, or logistics industry, understanding the benefits and functionality of pallet wrappers and stretch wrap machines is crucial. From increasing productivity and reducing labor costs to protecting your goods during transportation, these machines offer a range of advantages. Join us as we explore the different types of pallet wrappers and stretch wrap machines available, their key features, and how to choose the right one for your specific needs.

Ready to revolutionize your packaging process? Let’s dive into the world of pallet wrappers and stretch wrap machines and unlock the secrets to maximizing efficiency in your operations.

Section 1: Understanding Pallet Wrapping Machines

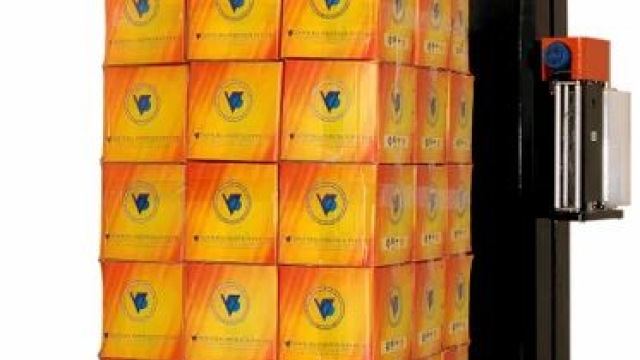

Pallet Wrapping Machines are essential tools for businesses involved in packaging and shipping large volumes of goods. These machines provide an efficient and automated way to secure and protect palletized loads during transportation. By using a stretch wrap film, pallet wrappers tightly bind the products together, ensuring stability and minimizing the risk of damage.

One of the key benefits of using a pallet wrapping machine is the increased efficiency it brings to the packaging process. Compared to manual wrapping methods, these machines can wrap pallets rapidly and consistently, saving valuable time and effort. With adjustable settings, they provide flexibility to accommodate different load sizes and wrapping preferences, making them suitable for a wide range of industries.

The stretch wrap film used in conjunction with pallet wrappers is a crucial component for successful wrapping. This specially designed film is highly stretchable, allowing it to be tightly wrapped around the load and create a secure bond. The film’s elasticity enables it to apply consistent tension throughout the wrapping process, ensuring the load remains stable during transit. Additionally, stretch wrap films come in various thicknesses and strengths to meet specific packaging requirements.

Understanding the basics of pallet wrapping machines and their associated stretch wrap films is essential for businesses looking to maximize efficiency in their packaging operations. These machines not only streamline the wrapping process but also contribute to reducing material waste and optimizing the overall supply chain. In the following sections, we will explore different types of pallet wrappers available and provide valuable tips to enhance the efficiency of your pallet wrapping processes.

###Section 2: Choosing the Right Stretch Wrap Machine

When it comes to selecting the perfect stretch wrap machine for your needs, there are several factors to consider. By carefully evaluating your requirements, you can ensure that you choose a machine that maximizes efficiency and productivity. Here are some key points to keep in mind:

-

Understanding Your Wrapping Needs: Start by assessing your specific pallet wrapping needs. Consider factors such as the size and weight of the loads, the frequency of wrapping, and any special requirements for the products being wrapped. This will help you determine the level of automation, speed, and capacity that your stretch wrap machine should have.

-

Machine Features: Different stretch wrap machines come with a variety of features that cater to different needs. Some machines offer adjustable wrap tension control, which allows you to customize the tightness of the stretch film. Others may have pre-stretch capabilities, which stretch the film before wrapping, minimizing the amount of film used. Consider the features that are crucial for your operations and choose a machine that offers them.

-

Consider your Budget: Along with functionality, it’s essential to consider your budget constraints. Determine your spending capacity and look for machines that align with your financial goals. Remember that while investing in a high-quality stretch wrap machine may require a larger upfront cost, it can lead to long-term savings through increased efficiency and reduced film usage.

By carefully considering your wrapping needs, machine features, and budget, you can choose the right stretch wrap machine that will maximize efficiency and make the pallet wrapping process seamless and cost-effective.

Section 3: Best Practices for Maximizing Efficiency

In this section, we will discuss some best practices that can help maximize efficiency when using pallet wrappers and stretch wrap machines.

-

Optimize Film Usage:

Efficiently using stretch wrap film is crucial in maximizing efficiency. To achieve this, it is recommended to use appropriately sized film rolls based on the pallet size and load weight. Additionally, make sure to adjust the tension settings on the stretch wrap machine to achieve the desired level of containment while minimizing film waste. -

Proper Load Preparation:

Preparing the pallet load correctly before wrapping is essential for efficient wrapping. Ensure that the load is stable and properly stacked, with no overhang or loose items. Using corner boards or edge protectors can provide additional stability and help prevent damage during transit. Taking time to properly align the load with the corner of the pallet can also help improve wrapping efficiency. -

Train Operators:

Providing adequate training to operators is crucial for maximizing efficiency. Operators should be trained on the correct operation of the pallet wrapper and stretch wrap machine, as well as understanding the different settings and adjustments that can be made. By having skilled operators, the risk of errors and inefficient wrapping can be significantly reduced.

By implementing these best practices, businesses can optimize their use of pallet wrappers and stretch wrap machines, ultimately leading to improved efficiency and cost savings. Remember, selecting the right equipment, using proper techniques, and investing in operator training are key factors in maximizing the benefits of these machines.